Onze onderhoudstips voor je HACO Plooibank

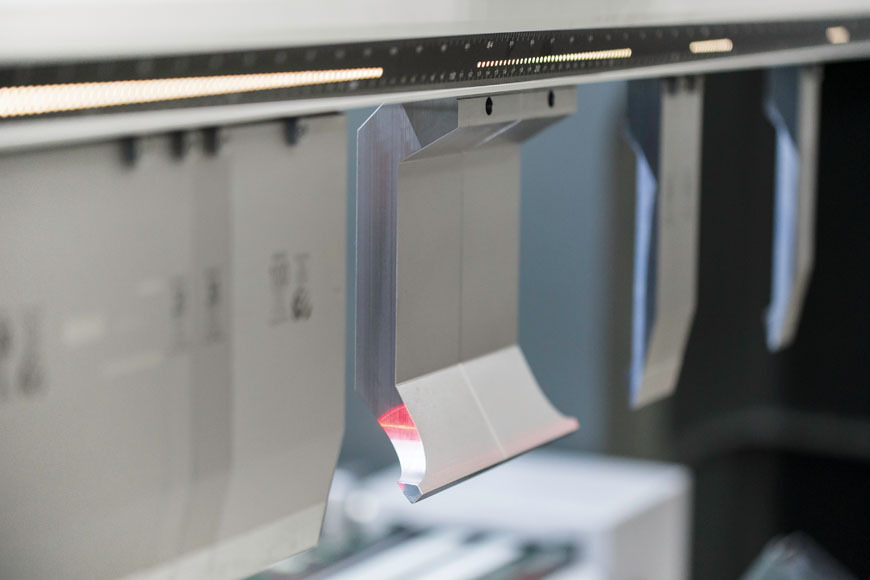

Bij HACO begrijpen we dat goed werkende plooibanken essentieel zijn voor het reilen en zeilen in jouw bedrijf.

Regelmatig onderhoud zorgt er niet alleen voor dat je onverwachte storingen kunt vermijden, het zorgt er ook voor dat je machine beter presteert. En dat zorgt dan weer voor hoogwaardige afwerking in al je plaatbewerkingsprojecten.

We zetten klantenservice op de eerste plaats en delen daarom onze tips met je

Door onze praktische aanbevelingen te volgen, kunt u de prestaties van uw machines optimaliseren, de levensduur verlengen en ongewenste stilstand voorkomen. Voorkom problemen zoals hydraulische lekkages, elektrische storingen en mechanische slijtage – en zorg dat uw productie altijd soepel blijft draaien.

Dagelijkse checkup:

- Reiniging: Verwijder stof en vuil, houd de omgeving veilig.

- Inspectie: Controleer bewegende delen, slangen en elektrische verbindingen. Let op ongewone geluiden.

- Veiligheid: Test noodstops en controleer veiligheidsafschermingen.

Wekelijkse routine:

- Inspecteer riemen, slangen en hydraulische leidingen op slijtage.

- Test buig- en achteraanslagbewegingen voor een soepele werking.

- Controleer hydraulische vloeistofniveaus en smeer indien nodig

Weekly Maintenance

- Visual Inspection:

- Conduct a thorough visual inspection of the machine, looking for any signs of wear, damage, or unusual noises during operation.

- Pay special attention to belts and hoses, checking for cracks, fraying, or other signs of deterioration that could lead to future issues.

- Operational Checks:

- Test the machine’s functions, including the bending strokes and back gauge movements, to ensure everything operates smoothly.

- Verify that the machine responds correctly to control inputs and that all movements are fluid and without hesitation.

- Hydraulic System Inspection:

- Check for any leaks in hydraulic lines, ensuring that all connections are secure and free from signs of wear.

- Inspect hydraulic fluid levels, topping off as necessary to maintain optimal performance.

- Examine hydraulic filters for clogs or contamination, replacing them if they do not meet cleanliness standards.

- Lubrication Check:

- Review lubrication levels in all moving parts, ensuring that they are adequately lubricated according to the machine’s specifications.

- Apply lubricant to any areas that may require additional attention, focusing on high-friction components.

Monthly Maintenance

- Comprehensive Cleaning:

- Remove all accumulated dust and debris from the machine's exterior and interior components.

- Pay special attention to areas around the hydraulic cylinders, electrical panels, and moving parts.

- Use appropriate cleaning agents that do not damage machine surfaces.

- Calibration:

- Check the accuracy of the machine settings and recalibrate if necessary to ensure precision in operations.

- Verify the accuracy of the bending angles and back gauge settings

- Major Inspections:

- Inspect all mechanical components, including gears, bearings, and linkages, for signs of wear or damage.

- Tighten any loose bolts, nuts, or fittings to prevent mechanical failures during operation.

- Check the condition of the hydraulic seals and replace any that show signs of wear or leakage.

- Electrical System Check:

- Conduct a thorough inspection of all electrical components, including relays, contactors, and circuit boards, for signs of wear or damage.

- Test all safety and emergency stop functions to ensure they are operational.

Annual Maintenance

- Deep Cleaning: Engage in a thorough cleaning of all components, focusing on intricate areas that may not receive regular attention.

- Professional Service Check: Schedule a professional servicing of your press brake, including hydraulic system checks, mechanical inspections, and software updates.

- Documentation of System Inspections: Conduct a systematic inspection of all systems, ensuring every part is functioning as intended.

- Review Operational Procedures: Re-evaluate operational guidelines and safety procedures to ensure all operators are up to date with best practices and safety measures.

Ask Your Local HACO

At HACO, we pride ourselves on providing personalized support with a strong understanding of the local market. Each machine is unique, and we’re prepared to give you the tailored guidance you need.

If you have any questions or need extra help with your hydraulic shear maintenance, please don’t hesitate to reach out. Our experienced team is ready to assist you and keep your equipment running smoothly.

If you’d like to explore our products or services further or have specific maintenance questions, please contact us today!