Higher Production Speeds with the EuroMaster-S

At PCMA, a metalworking company specializing in square silos in Flavin, Aveyron (FR), production efficiency has significantly improved thanks to the implementation of a HACO EuroMaster-S 36150. This upgrade has enabled faster deliveries to customers in the industrial, agricultural, and private sectors. With the Euromaster-S, higher production speeds have been achieved, supported by intuitive software, greater precision, and increased autonomy. The machine was supplied by FHAMO, our distributor in South-France.

Simplified Handling for Less Labor-Intensive Production

The standout feature of this machine is its sheet support system, which simplifies handling, particularly for their flagship product: silos. Combined with user-friendly integrated software, which ensures a smooth learning curve for operators, this has allowed PCMA to save significantly on time and labor. As a result, they have achieved higher production rates with the same team of employees.

The HACO Press Brake: Features and Benefits

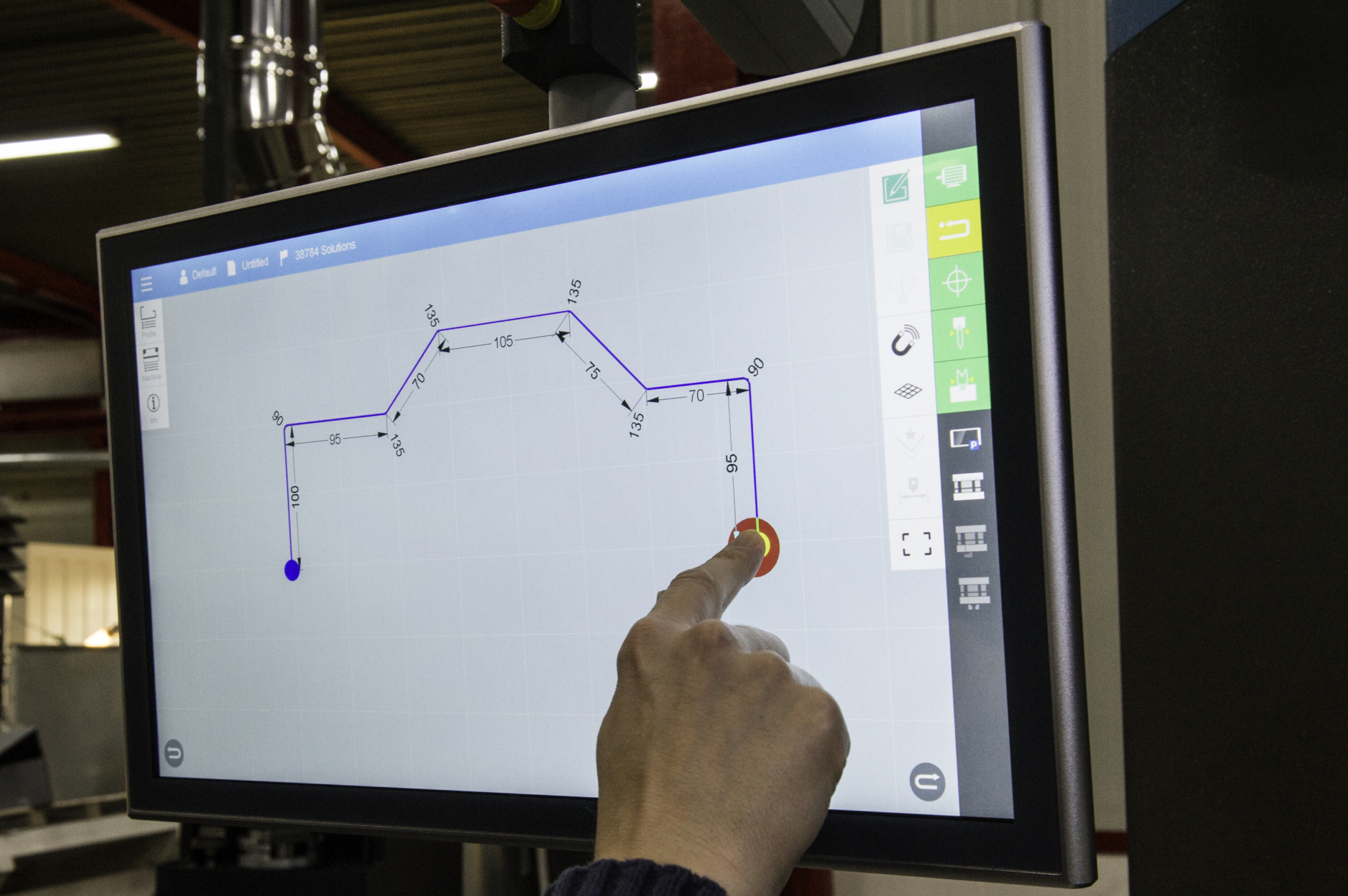

PCMA selected the HACO Euromaster-S 36150 press brake, equipped with advanced features such as Fastbend-2D MT controls and a sheet-following system. The Euromaster-S provides a total bending length of up to 3.6 m. These features streamline production processes, enabling more efficient manufacturing of recurring products like silos as well as custom projects.

Quick Support Boosts Production

PCMA values the swift response and technical expertise of HACO’s support team. Rapid assistance and problem-solving are crucial for the seamless daily operation of their machines.

PCMA’s experience with HACO machines highlights the transformative impact of advanced production technology on small-scale operations, enhancing efficiency and quality in metalworking production.

Learn more about EuroMaster-S

Multi level press brake with market oriented execution. Extensive choice of options, both basic and sophisticated. Innovative 2D Multi Touch graphical control. Excellent price performance ratio. Integration of advanced safety equipment.

The Euromaster- S series comes standard with the intuitive FASTBEND-2D MT Premium control. The Multi Touch technology application reduces the number of keyboard and button actions to an absolute minimum. The innovative Smart Draft, Design/Bending Sequence Multitasking, Step Previewer, Combined Icons and Auto Tooling features provide simple, intuitive control of the entire production cycle

Want to know how HACO can help your company optimize your production? Get in touch with us!