Operations

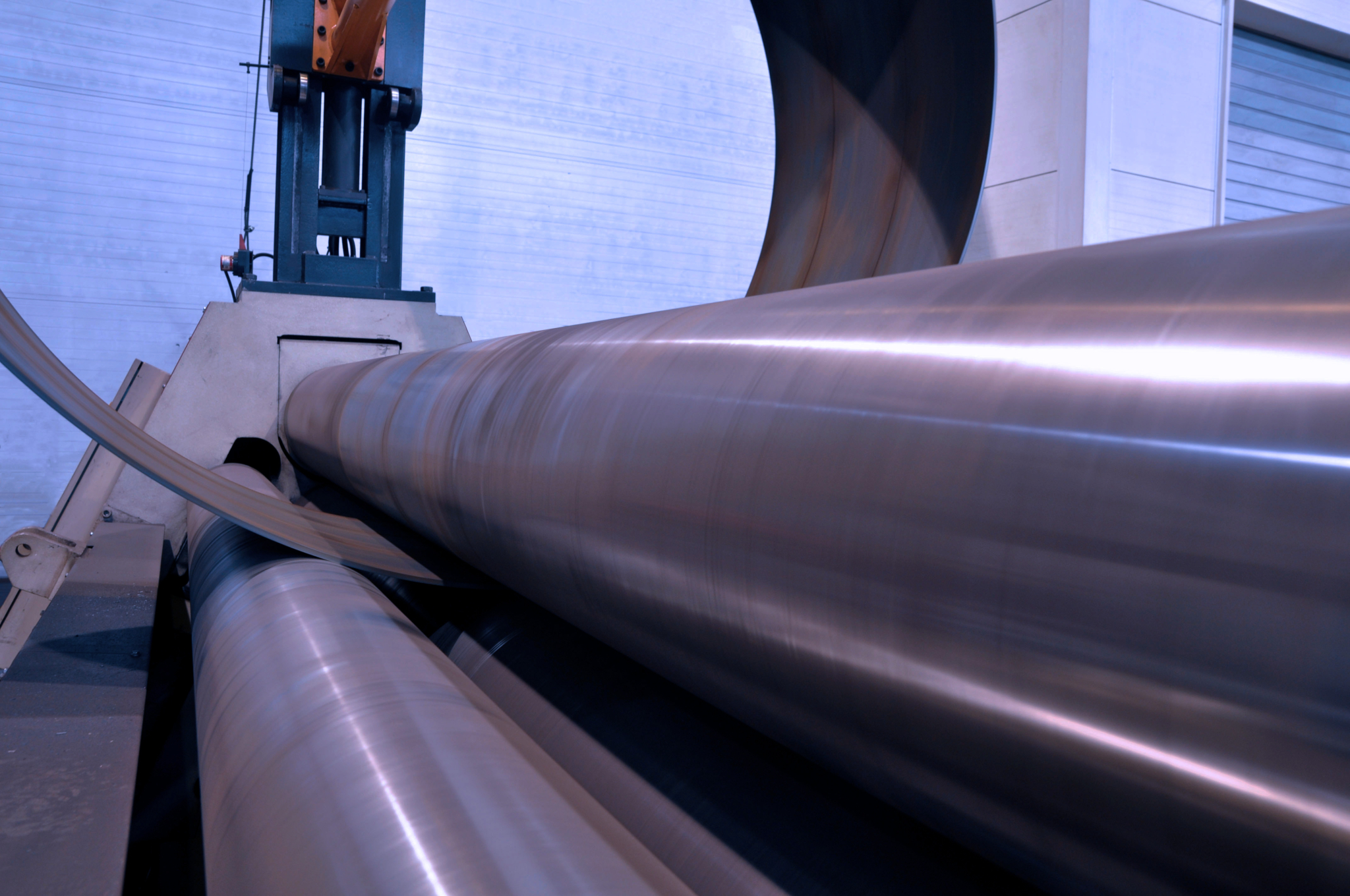

Roll bending

Roll bending is an advanced technique in sheet metal machining. It allows craftsmen to create precise shapes and structures that meet specific design requirements. Using sheet rolling machines and profile rolling machines, it is possible to transform sheet metal. HACO specializes in offering some state-of-the-art roll bending machines.