Bending

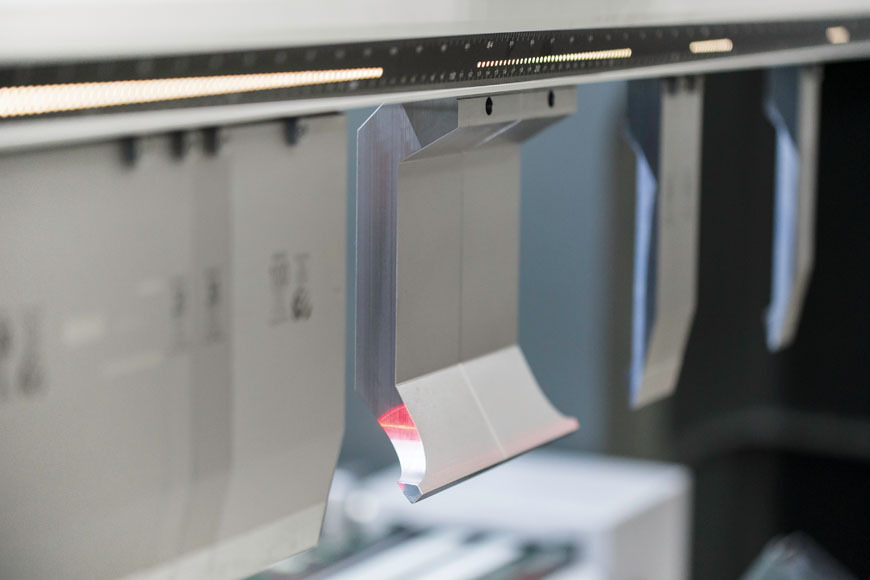

Press brakes are used in a wide variety of industries. From automotive to shipbuilding, press brakes are used to bend steel sheets, or sheets from other materials, into pre-programmed shapes between a die and a punch.

The press brake uses hydraulic, mechanical or electric power to move the upper bending beam downward. This bending bar presses the metal against a lower support or die, bending the material into the desired shape.

Advantages

Thrustworthy machines

The accuracy and reproducibility of bends make press brakes indispensable in various industries, including sheet metal working, body building, aerospace, and construction. These machines offer the capacity to achieve complex shapes, making them an essential role in manufacturing metal components in an efficient and standardized manner. The ability to produce exact bends not only contributes to the precision of finished products, but also improves overall productivity and consistency within the manufacturing process.

Equipped with modern software

HACO's press brakes come standard with advanced control systems. Innovative features such as Smart Draft, Step Previewer and Combined Icons contribute to easy and intuitive control of the entire production process. Thanks to these groundbreaking features, the operation of HACO press brakes is extremely user-friendly, making them suitable for operators of different experience levels. Whether beginners or experienced professionals, HACO control systems provide a streamlined and accessible user experience throughout the production cycle.